I note down interesting points from DIN-Handbook 523 as follows:

DIN IEC 98 (October 1989): Analoge Schallplatten und -Abspielgeräte; Identisch mit IEC98:1987(Analogue audio disk records and reproducing equipment: same as IEC 98:1987)

I was in doubt about my rapid reading of IEC60098 (original in French/English) and perused this German translation. I make following notes about the inner/outer groove radius.

- From clause 8.5: The outer recorded groove radius shall be less than 146.3mm.

- From clause 8.8/8.9: The inmost recorded groove radius for 30cm LP can be interpreted in various ways. No specific value, but I assume more than 59.6mm as intermediate value between 56-63.2mm where finishing groove radius (53.2mm±0.4mm) + one turn of lead-out groove pitch (6.4mm±3.2mm) = inmost recorded groove radius. Then minimum 57.5mm in DIN is covered by extreme minimum 56mm in this IEC because DIN/IEC adopted same specifications about finishing groove radius and lead out pitch.

I find an interesting article about distance from the centre of mounting holes of cartridge to stylus tip. Fig.2 in connection to clause 11.5 shows 9.5mm±1mm at recommended tracking force. This clause 11.5 recommends: mounting screw M2.5 (or M2.6 where M2.5 is not available) and cartridge weight (mass) not exceeding 12g. Tip distance 9.5mm is derived from 3/8 inch as often Shure cartridges have such value. In JIS C5503(1979) Phonograph pick-ups, tip distance is indicated as 10mm±3mm (wide enough for almost all cartridges to fall in this range) showing simple drawing (total length max. 60mm from pin to head and max. 18mm from center of mounting holes to head). It is only a matter of conventional practice and depends on the products available or most popular at the time. The strange recess min. 5mm in Fig.2 may be designed according to then current SME type of headshell having the rim bent for reinforcement.

Clause

8.1 Direction of groove modulation: suitable vertical tracking angle (VTA) is

20degree +5/-0. The resulting modulation shall be optimum for

reproducing styli having a rake angle (SRA) of between 0 and -5degrees.

I think effective vertical modulation angle (VMA) recorded in

vinyl should match vertical tracking angle (VTA) for cartridge. Recommended VTA (and VMA) in

60's

was about 15degrees and then in 70's it became 20degree +/-5 and from early 80's

it

became 20degree +5/-0. VMA is not equal to cutter head angle on lacquer. The cutter head should be more inclined than effective modulation angle due to

the elasticity of lacquer. IEC98-1964 & BS1928-1965 have a following NOTE:

"In practice, angles of between 0degree and 25degrees may be

encountered" . VTA of

cartridges in early '60 was ranging between 8degrees (Neumann DST1212) and

36degrees(Shure M77) -see VTA of old cartridges.

In

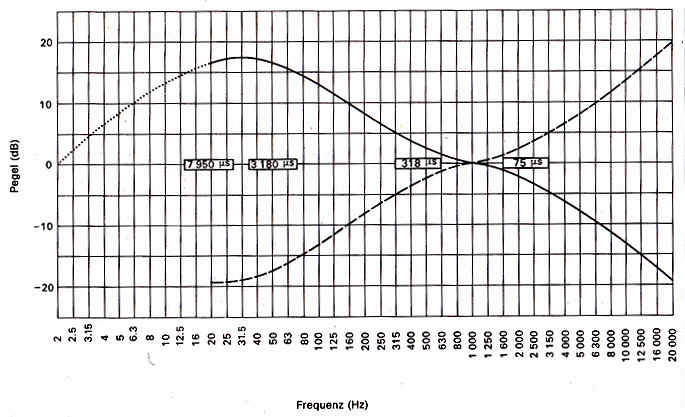

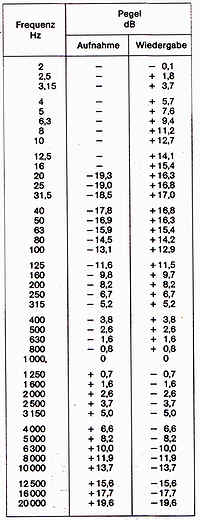

comparison with RIAA(3180/318/75μs, 50/500/2120Hz), this IEC (clause

10.2.1) suggests an additional time constant 7950μs/20Hz in order to

suppress subsonic noise. It results in 3dB difference at 20Hz between recording and

reproduction as under. Clause 10.2.2 Tolerance for reproduction chain: a) 2-20Hz

reproducing curve should be on or under the dotted line b)20Hz-20kHz no

tolerance is stipulated. In practice some preamplifiers are equipped with

subsonic filter 12dB/Oct under 15Hz for the same effect since IEC time constant

(and its curve 6dB/Oct) is an example. IMO: Historically speaking the bass

limit for phono amplifier is changing by time. Before 1950 low limit was often

not stipulated since there was natural bass limit in

microphone/amplifier/speaker. Later in Hi-Fi era after developing LP, the

handling frequency for microphone/amplifier/speaker has been much extended and

there arises a need for suppressing rumble noise (and low frequency resonance

between arm mass and cartridge compliance which has became lower than 20Hz).

"Nominal" low limit: year 1948 Columbia LP 100Hz>1954 RIAA

50Hz>1987 IEC additional 20Hz. If you are interested in equalizations,

please look into my equalizations.xls in spread

sheets (1987 IEC revision is shown in EXAM sheet).

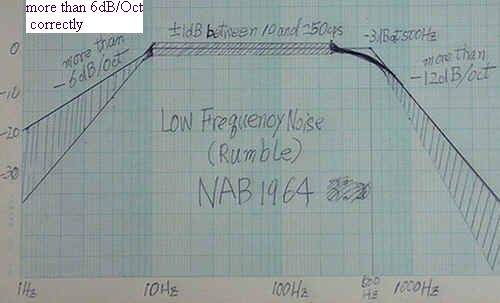

NAB(1964) specified reproducing characteristic

between 30Hz-15000Hz and recommended that "the system response below 30 cps and

above 15,000 cps be attenuated at least 6 db per octave with the 3 db points at

20 cps and 16 kc." Cut under 20Hz is to avoid intermodulation,

cut from 16kHz is to supress harmonic distortions by tracing on

record. I appreciate NAB's foresight.

1)

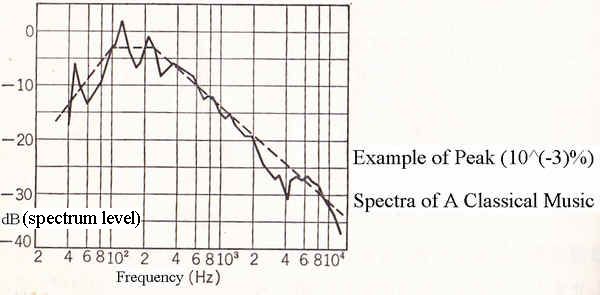

The conventional "hearing range 20Hz-20000Hz" is often misunderstood.

Hearing field represents normal characteristic

as is. Range of audible frequencies in music is

narrowed for usual and lower sound levels. This fact is the reason why we can

enjoy old recordings (musical balance) in every format. The difference

among various formats can

be attributed to dynamic range (Shellac 30-50dB, Vinyl 66dB

and CD 85dB) and genre of music corresponding to the required sound levels:

(roughly) Vocal +/-20dB and Symphonic +/-35dB from central sound level 60dB-65dB. One would like to pay attention to peaks or limits and ignore average:

mixing up theoretical/nominal/potential values (big numbers)

with

practical/real values. Music or

art is not point game. There is no license nor superior hearing ability

required to enjoy music.

2) Meanwhile hearing data were

usually collected from some healthy adults: 18-25 years old in case of

ISO 226 Acoustics - Normal equal-loudness-level contours (2023). Older

adults are not counted as "normal" from the viewpoint of otology. It will express

softly "informative" instead of "normative" data in accordance with recent

compliance.

3) Most audiophiles would not check their ears with frequency

record: often resulting in discouragement (one's pride is shattered). Some

measurements of audio gear

are found welcome, but the measurement of own ears is unwelcome.

IEC 60098(IEC98-1987) is modifying or replacing DIN 45538(definitions of disk record reproducing equipment), 45539(guidelines for measuring method, specifications, connection, exchangeable pickup system, requirement on reproducing amplifier etc), 45546(StereoRecord 45rpm), 45547(StereoRecord 33rpm) and 45548(criteria for record reproducing equipment). The following are extracts mainly from DIN standards.

DIN 45500 T3 (1975):Heimstudio-Technik (Hi-Fi); Minderstanforderungen an Schallplatten-Abspielgeräte (Hi-Fi technics; requirements for disk record reproducing requirements)

This

standard is almost similar to IEC 60581-3(1978) defining minimum performance requirements.

Both standards mentioning: allowable deviation from rated speed +1.5%-1%/wow and

flutter ±0.2% maximum/Rumble ratio more than 35dB unweighted and 55dB weighted

(in addition to rumble IEC specified reference signal-to-hum ratio more than

50dB at reference velocity 3.83cm/s rms and reference frequency 315Hz)/static

VTF maximum 0.03N/channel unbalance less than 2dB at 1kHz/channel separation

over 15dB between 500Hz (315Hz in IEC) and 6300Hz: over 20dB at 1kHz/VTA

20±5degrees. This standard comments on compliance (static measured) for

every direction to be minimum 0.8cm/N (8x10^[-6]cm/dyne) corresponding to the

maximum braking force (resilience=Rückstellkraft) 7.5mN(0.75p) measured

at displacement 60μm. The compliance for lateral direction shall be bigger

than that for vertical direction. Further mentioning: rated output voltage of

velocity sensitive pick-ups (for example magnetic cartridges) to be 5 to 15mV at

1kHz with load 47kΩ for peak velocity 10cm/s (channel sensitivity 0.7 to

2mV/cm/s as per IEC). In case of displacement=amplitude sensitive pick-ups

such as piezoelectric cartridges: 0.5 to 1.5V with load 470kΩ for peak

velocity 10cm/s. FIM (frequency intermodulation) distortion at tracing -6dB

reference tone shall be lower than 1%. Standard spherical stylus tip radius

15+3-0μm and standard bi-radial tip radius 6μm and 18μm.

This IEC specified

separation of R from L and L from R respectively and made note: Separation and

crosstalk are equivalent only if there is no unbalance output between R/L.

In

IEC98-1987: Separation precedes crosstalk because separation is independent of

channel sensitivity. Hence playing back test record with R or L signal

alternatively, the separation of channel L from channel R: 20log(L output

voltage from L channel signal divided by L leakage voltage from R channel

signal), the separation of channel R channel from channel L: 20log(R

output voltage from R channel signal divided by R leakage voltage from L channel

signal). And indicate smaller value of measured channel separations at 1kHz.

Allowable deviation from rated speed

+1.5%-1% is too large. Provided the speed deviation +/-0.2% is allowed, the drift of

strobe-patterns shall be as following table. To get exact 45rpm at

50Hz, patterns should be drifting -15/minute. See also my

EXCEL file for rpm & strobe pattern designs. IEC98-1987: Besides using

conventional strobe disc (method A), 120 revolutions of a record are timed by

means of a stop watch (method B) for T 160seconds for 45rpm or T

216 seconds for 33 1/3rpm defining the mean deviation as (T-t)/t x

100% where t shall mean the measured time passed during 120

revolutions. Measuring method B is accurate because it is independent of the

power supply frequency deviations for strobe light. Hence in some turntables

equipped with quartz-locked signal generators, the generated signals are used

for motor control and strobe light.

My note about

the sensitivity

of cartridge: The velocity of groove modulation is usually expressed as peak

cm/s while output voltage is conventionally shown as mVrms in accordance with

the indication of millivoltmeter. Relative output in this DIN (5 to 15mVrms

for peak velocity 10cm/s) is equivalent to sensitivity in IEC

expression (sensitivity 0.7 to 2mV/cm/s where output mV and velocity

cm/s are both either effective [rms] or peak values). DIN45500

&45539 about cartridge output were often misused and outputs were expressed

incorrectly as "mV/cm/s or mVs/cm" while original DIN indicated

relative output in mVrms for peak recorded velocity. IEC 60581-3 was based

on DIN, but maybe IEC people became aware of such misuse as simple division of

rms by peak. I did not know this fact untill I noticed the difference of

respective output numbers as described in DIN and IEC. See also the

English part of "frequency record" (output test of 4 monaural

cartridges). In German text,

peak velocity is marked with symbol v^ while effective velocity is marked with veff.

Accordingly all the velocities (cm/s) quoted hereunder shall mean peak values if

not specified.

|

50Hz Power Supply (Mains) |

60Hz Power Supply (Mains) |

||||

| RPM | number of stripes or dots on strobe disc | drift number per minute | RPM | number of stripes or dots on strobe disc | drift number per minute |

| 77.92 | 77 | -6 to +18 | 78.26 | 92 | -38 to -10 |

| 45.11 | 133 | -27 to -3 | 45.00 | 160 | +/-14 |

| 33 1/3 | 180 | +/-12 | 33 1/3 | 216 | +/-14 |

According to JIS C5521-1975 (phonomotor test method): 100/3 revolutions at groove radius 12cm and 45 revolutions at groove radius 8cm are measured with the usual stylus pressure on each plain groove. IMO: Because of stylus pressure (& drag force) influencing on turntable, rpm would be increasing a bit toward inner groove in most turntables other than Direct Drive turntables. Diameter of the conventional Strobe Disc (around 10cm) was made similar to the label size for checking rpm with record putting on turntable. We amateurs forget this reason and feel happy to have bigger strobe disc and measure rpm without loading of stylus pressure upon record!

DIN 45538 (1969):Begriffe für Schallplatten-Abspielgeräte (Definitions for disk record reproducing equipment)

This standard defined terms such as relative deviation from nominal RPM/Wow and flutter/Margin for rumble/pick-up system/cartridge/stylus/tracking force/resilience (Rückstellkraft)/compliance/channel separation/VTA/reproduced frequency/effective stylus mass etc. 'Rückstellkraft' is defined as a force which must be overcome by stress force so that stylus tip can be moved from set position. Tracking force/Resilience/Compliance can be measured at null frequency (static) or at specific frequency (dynamic). IMO: The term 'Rückstellkraft' is identical to stiffness as 1/compliance for example 2g/100micron=980*2dyne/0.01cm=196000dyne/cm stiffness which can be converted into static compliance about 5.1*10^(-6)cm/dyne.

DIN 45541 (1971):Frequenz-Mess-Schallplatten (Frequency test record St 33 and M33, Stereo and Mono)

St 33(Stereo:side A) contains Sweep from 31.5Hz to 20,000Hz(L/R), 16 spots Signals for same range. M33(Mono:side B) contains sweep from 31.5Hz to 20,000Hz, 16 spots signals for same range and sweep from 5 to 125Hz (flutter range). 8cm/s for stereophonic recording, 10cm/s for monophonic recording were selected each as reference recorded velocity 0dB in 70's. See also DIN 45543 which amended velocity 0dB for monaural recording: from conventional 10cm/s to correct 11.3cm/s as calculated.

DIN 45542 (1969):Verzerrungs-Messschallplatte (Distortion test record St 33 and St 45, Stereo)

Side:A St33: recorded

vertically=hill and dale modulation Tiefenschrift, this side for the

measurement of VTA is recorded at various vertical modulation angles from 6 to

30 degrees with complex (Doppel) tones of 1850Hz+3150Hz & 370Hz+630Hz for

measuring vertical tracking angle of a cartridge. Velocity of each frequency

component is fixed at 3.8 cm/s. When the output of total tone 5000Hz or 1000Hz

is measured lowest, the ring shall indicate corresponding vertical tracking

angle of a cartridge. Vertical tracking angle measured with total

tone 1000Hz shall be declared in data sheet.

Side:B St45/33: recorded on flank(45 degrees)=Flankenschrift (vertical

modulation angle fixed at 15degree) 300Hz+3000Hz for 33rpm or nearly

400Hz+4000Hz for 45rpm for the test of nonlinear distortions with stereo

pick-ups. 0dB: f1=300Hz with velocity 8cm/s, f2=3000Hz with velocity 2cm/s, i.e.

velocity rate is 4:1 for 300Hz/3000Hz (11cm/s:2.8cm/s for nearly 400Hz/4000Hz). Playing with 33.3rpm,

frequency intermodulation distortion (FIM) can be measured by determining

the degree of frequency modulation of f2 by f1. Ortofon often declares these data for their cartridges

as FIM distortion at recommended tracking force, DIN 45542: <

1% etc. Wow-flutter/Drift meter in accordance with DIN 45507 can be applied

with this frequency pair (300Hz+3000Hz). Instead of weighting filter, switch on

RC HPF with time constant 1ms (=around 160Hz) enabling to suppress frequency

modulation (FM) caused by wow-flutter of turntable.

Playing with 45rpm, intermodulation distortions (IMD) in

accordance with DIN 45403 can be measured. Search-tone-analyser (FFT?) is

recommended since demodulation method (amplitude demodulation) may indicate

false value of distortion arising at tracing (Phase modulation). Geometric

distortion due to stylus tip shape is compensated upon recording except for two

rings - cartridge with stylus tip radius 15μm and vertical tracking

angle 15degree shall be used as standard for this test record (see my note

1). The rate of nonlinear

distortions arising at -6dB reference tone shall be declared in data sheet.

See also DIN 45549 about FIM. The publisher Beuth released test record

based on 45542 manufactured by TELDEC (recorded by DG). My Personal Notes: 1)By 1969 TELDEC (US Patent

3457374 etc) developed tracing simulator for compensating

expected geometric distortion due to the spherical stylus tip tracing on

groove. But then the respective designed curvature of spherical stylus tip must

be used? About such question JVC engineers explained in a Japanese book (1979)

that "in any case tracing distortion is reduced as if smaller tip radius is

used because |r-r0|<r (r: applied stylus tip radius, r0: designed value of

stylus curvature for tracing compensator)" see a

drawing introduced in my Japanese page about tracing simulators & recording compensators.

2)FIM & IMD. I am wondering how two

different measuring items (FIM and IMD) in accordance with speeds are possible while the

nature of recorded signals is essentially same? There have been various terms

and different approaches to modulation distortion measurement: CCIF IMD/SMPTE

IMD/DIM

(dynamic

intermodulation distortion) /Thiele IMD (total difference frequency distortion)

and so on!!!

| Side A: Vertical Tracking Angle Test with complex (Doppel) tone in vertical modulation | ||||||||

| Band | Vertical Modulation Angles | f1 (Hz) | f2 (Hz) | velocity for f1 (v1)=velocity for f2 (v2) (cm/s) | recorded time (second) | Sum tone f1+f2 (Hz) | ||

| A1 | 6/10/14/18/22/26/30 degrees (total 7 rings) | 1850 | 3150 | 3.8 | each 10 | 5000 | ||

| A2 | 6/10/14/18/22/26/30 degrees (total 7 rings) | 370 | 630 | 3.8 | each 10 | 1000 | ||

| Side B: Non-linear Distortions Test at 45degrees components. | ||||||||

| Band | Ring number within band | Channel | Relative level (dB) | recorded time St33 (second) | Remarks | |||

| B1 | 1/2/3/4/5/6/7 | L | -12/-10/-8/-6/-4/-2/0 | each 12 | ||||

| B2 | 1/2/3/4/5/6/7 | R | -12/-10/-8/-6/-4/-2/0 | each 12 | ||||

| B3 | L | -6 | 35 | Representative Level for FIM measurement | ||||

| B4 | R | -6 | 35 | Representative Level for FIM measurement | ||||

| B5 | 1/2/3/4/5/6/7 | L | -12/-10/-8/-6/-4/-2/-6 | each 12 | Geometric tracing distortion is not compensated upon recording for ring No.7. | |||

| B6 | 1/2/3/4/5/6/7 | R | -12/-10/-8/-6/-4/-2/-6 | each 12 | ||||

| St45: rotation at 45rpm for side B | f1=400Hz* | velocity 11 cm/s | 0dB | |||||

| f2=4000Hz* | velocity 2.8 cm/s | |||||||

| St33: rotation at 100/3rpm for side B | f1=300Hz* | velocity 8 cm/s | 0dB | |||||

| f2=3000Hz* | velocity 2 cm/s | |||||||

Remark* on rotations and frequencies: Recorded frequency is shown 1% lower at 100/3rpm and 1% higher at 45rpm because 45:100/3 is not exactly 4:3. My note: Exact ratio 45rpm divided by 100/3rpm =1.35, hence above four velocities for 0dB seem to be rounded approximately while frequency ratio of f1:f2 retains exact vale 1:10 and velocity ratio 4:1. |

||||||||

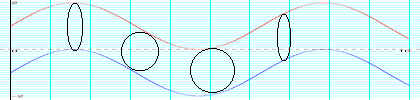

I picked up the following pictures from Yamamoto (1971). Left upside: Reproduced wave by cartridge of VTA 16 degrees tracing on test tone of 400Hz+4000Hz recorded with VMA 2.5 degrees. Left downside: Wave of 4000Hz component. Right: 4000Hz component reproduced with VTA 16 degrees cartridge on test tone 400Hz+4000Hz recorded with VMA 15degrees. The difference 13.5 degrees between VMA & VTA might be an extreme case. But it is not impossible if we consider VMA variation of stereophonic records from 15 to 23 degrees & VTA variation of actual cartridges deviating +/- 5 degrees from nominal value. [8+5=13].

DIN 45543 (1984):Meßschallplatte zur Messung des Frequenzganges und der Kanaltrennung (Frequency response and separation test record)

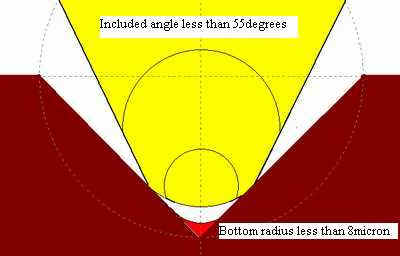

This record combines frequency test (sweep 20 to 20,000Hz Lateral), channel separation test (spot 20 to 20,000Hz Alternating L/R), and arm resonance test (3 to 500Hz Lateral and Vertical): thus replacing older test record DIN45541(Stereo and Mono) technically. This test record made in accordance with DIN45547-1981(Stereophonic disk record 33 1/3rpm) should have bottom groove radius smaller than 4micron and VMA 23degrees for stereophonic recordings. A test record based on this standard was produced by DGG.

| Band | Kind of Recording | Effective value cm/s | Peak value cm/s | REMARKS | ||

| Side A: signals are recorded with DIN/IEC/RIAA characteristic/time constants 3180-318-75microseconds. | ||||||

| A1 | Lateral | 8 | 11.3 | Reference Tone Level = 0dB 1kHz 15seconds | ||

| A2 | Vertical | 8 | 11.3 | Reference Tone Level = 0dB 1kHz 15seconds | ||

| A3 | Left Channel | 5.6 | 8 | Reference Tone Level = 0dB 1kHz 15seconds | ||

| A4 | Right Channel | 5.6 | 8 | Reference Tone Level = 0dB 1kHz 15seconds | ||

| A5 | Left channel | -10dB level of band A3: sweep from 20Hz to 1kHz and -20dB sweep from 1kHz to 20kHz | ||||

| A6 | Right channel | -10dB level of band A4: sweep from 20Hz to 1kHz and -20dB sweep from 1kHz to 20kHz | ||||

| A7 | L/R alternative | -20dB 1kHz | ||||

| A8-A18 | L/R alternative | -20dB spot 20kHz/18kHz/16kHz/14kHz/12.5kHz/10kHz/8kHz/6.3kHz/4kHz/2kHz/1kHz | ||||

| A19-A27 | L/R alternative | -10dB spot 1000Hz/500Hz/250Hz/125Hz/80Hz/63Hz/40Hz/31.5Hz/20Hz | ||||

| A28 | L/R alternative | -10dB 1kHz | ||||

| Side B: signals are recorded with time constants 3180-318microseconds (excluding top lift 75microsecond). | ||||||

| B1 | Left channel | -10dB level of band B5: sweep 20Hz to 20kHz | ||||

| B2 | Right channel | -10dB level of band B6: sweep 20Hz to 20kHz | ||||

| B3 | Lateral | -10dB level of band B7: sweep 20Hz to 20kHz | ||||

| B4 | Vertical | -10dB level of band B8: sweep 20Hz to 20kHz | ||||

| B5 | Left channel | 5.6 | 8 | Reference Tone Level = 0dB 1kHz 15seconds | ||

| B6 | Right channel | 5.6 | 8 | Reference Tone Level = 0dB 1kHz 15seconds | ||

| B7 | Lateral | 8 | 11.3 | Reference Tone Level = 0dB 1kHz 15seconds | ||

| B8 | Vertical | 8 | 11.3 | Reference Tone Level = 0dB 1kHz 15seconds | ||

| B9 | Lateral | -22dB level of band B7 : sweep 3Hz to 500Hz | ||||

| B10 | Vertical | -22dB level of band B8 : sweep 3Hz to 500Hz | ||||

| VARIOUS TEST RECORDS measuring output voltage or SN ratio or output difference between L/R | DENON XG-7001 & JVC TRS-1007 etc | JIS Monaural Standard Record JIS C-5507 & JIS Stereo Standard Record JIS C-5514*(see bottom explanation) etc | NAB 1964 | DIN Test record | CBS-Lab STR-100 | |

| 1kHz reference level recorded in test record | Stereo (each channel i.e., L/R alternatively) 3.54cm/sec peak for 45 degrees | Lateral 5cm/sec peak | Lateral 7cm/sec peak | Stereo (each channel) 8cm/sec | Lateral 10cm/sec peak or 11.3cm/sec (DIN 45543) | Stereo (each channel i.e., L/R alternatively) 3.54cm/sec rms for 45 degrees |

| level of each one channel (45degrees peak) peak signal velocity conversion for stereophonic pickups | 3.54cm/sec | 3.54cm/sec | 5cm/sec | 8cm/sec | 7cm/sec or 8cm/s (DIN 45543) | 5cm/sec |

| Why lateral groove is used in JIS for measuring output voltage of stereo pickups? I think it is because of measuring output difference between L/R at a time. JIS C 5503-1979(Phonograph Pickups) explained clearly "lateral peak 50mm/sec should be converted to 35.4mm/sec peak 45degrees for stereo pickups". Please note the difference in definition between relative output (mVrms for certain velocity peak or rms) and absolute sensitivity (mV/velocity in IEC definition) as explained earlier. | ||||||

1) how about the relation between 0dB & recorded velocity?

According to Vinyl Lexikon by Frank Wonneburg published in year 2000: <following

to RIAA/IEC 8cm/s for stereophonic records, 10cm/s for monophonic records and

12cm/s for MaxiSingle>.

DIN 45537(1962)Monaural Records:peak

10cm/s at 1000Hz with the reservation that its value is to be approved

internationally. Later

10cm/s for monaural 1kHz test tone is replaced by 11.3cm/s. Often readers &

writers misunderstand the true intention of documents and overlook the time

when these documents were made (funny enough standards for vinyl records are

made a few years after the appearance of new products).

DIN 45547(1981)Stereophonic Records: effective

5.6cm/s (=peak

8cm/s) at

1000Hz

Any velocity level was optional/stopgap because to get same output level from

stereo & monaural grooves with

stereo cartridge:

stereo one channel recorded velocity towards 45degrees = monaural velocity/√2.

Hence 8x√2=11.3cm/s for monaural recording is indicated in the above table

from DIN 45543. Old 10cm/s might be derived from 7cm/s(NAB)x√2. Of course these are again optional and another pair (Stereo

channel-wise 3.54cm/s 45 degrees and Mono 5cm/s laterally) can be selected as

reference 0dB as often applied on cartridge sensitivity test. Each 0 dB level

can be different in every test record according to the purpose of measurement:

I prefer the description in velocity (cm/s) than obscure dB. 0dB as recording

level index cannot be standardised since the

actual recording level should be determined backward from the conventional

ability

of cutting machines and pick-ups.

2) how to measure recorded velocity?

According to IEC98: the alternating velocity that a rotating disk would impart

to the stylus of a pick-up having low

mechanical impedance and negligible dimensions of stylus tip.

Such perfect cartridge is not yet existing! Hence the recorded velocity of a

sinusoidal groove modulation may be measured with an optical method (the

Buchmann-Meyer light-band method measuring the width of reflected light

patterns). G. Buchmann und E. Meyer, Eine neue optische Messmethode fuer

Grammophonplatten. Electrische Nachr-Techn. 7(1930). Another method is based

on the theoretical/geometrical value of velocity: Peak

Velocity for sinusoidal modulation = amplitude or displacement of modulation

from centre (0 to peak)*2pi*frequency. For

instance "recorded velocity" 3.14cm/s: 5micron amplitude for 1kHz, 50micron for 100Hz and so on.

DIN 45544 (1971):Rumpel-Meß-Schallplatte (Rumble measurement test record St 33 and M 33, Stereo and Mono). The measuring method is based on DIN 45539.

Side

A: Stereo L flank/R flank & Vertical/Lateral Recordings 315Hz with peak

velocity 5.42cm/s and long plain groove until minimum diameter 120mm with normal recording

(dense) pitch to

test motor rumble.

Side B: Lateral=Monaural Recording 315Hz with peak velocity 0.54cm/s and long

plain groove until minimum diameter 120mm with pitch 0.54mm/turn (=0.3mm/s).

By

using level recorder: check rumble voltage, the strength of acoustic feedback

on turntable case or the influence of

auto-stop depending on groove radius.

The rumble voltage ratio=20log10(output at

315Hz peak 5.42cm/sec divided by output at mute groove)

There is a reference to NAB-recommendation in March 1964.

It is said that NAB's values (100Hz peak 1.4cm/s laterally recorded monaural) are

lower than values measured with this DIN test record: about -4dB for monaural

equipment and -7dB for stereo equipment because of velocity difference converted

to 1kHz output and the nature of groove modulation (DIN/IEC=Stereo 315Hz while

NAB=Monaural 100Hz). Moreover the measured value according to NAB is unweighted

only. 315Hz is selected because it is the limit of weighted curve as well

as linear section for evaluation. Peak velocity 5.42cm/s is selected because it

is comparable with velocity 10cm/s at 1kHz after passing IEC/RIAA equalization

(time constants 3180/318/75microseconds). But -5.32dB(=5.42/10) as

recording difference between 315Hz and 1kHz was not exact! Hence accurate value

5.51cm/s for 315Hz based on recording difference -5.18dB is adopted later

in IEC98(1987). IEC 60581-3(1978) also indicated 3.83cm/s rms (5.42cm/s

peak) based on old data from original RIAA etc before computer

calculation based on time constants became easy. The specific

recording/reproducing dB point at 300Hz instead of 315Hz had been indicated in

early documents and in early 1970s someone estimated dB for 315Hz and this incorrect figure

had been used repeatedly without checking. Now exponential divisions are

systematically adopted for frequency table i.e., x1.25 etc and/or rounded to

near integral numbers such as 100, 125, 160, 200, 250, 315 and so on because

each division has almost same distance on semilogarithm chart. The correct recording/reproducing dB

for 315Hz was indicated as 5.2dB (rounded from 5.179) in IEC98(1987). IEC98(1964)&BS-1928(1965) indicated correct

curve

for 20Hz-20kHz while the recording curve presented in DIN 45537-1962(Monaural LP

record) had irregularity for 30Hz-200Hz (30Hz -17.5dB in DIN45537-1962 vs

correct value -18.6dB in DIN45547-1981 for stereo LP) whereas time constants for

these standards remain unchanged irrespective of mono or stereo application. We

find this kind of small deviations in old documents. It was already known in

Japan by 1973 that original RIAA dB numbers had irregularity - JIS S 8502-1973

indicated correct dB up to the second decimal.

My note: SN rates are

actually differing by the radius of mute band to be tested. This point is

neglected in recent test data. In many cases SN ratio at inner groove is better

than SN ratio at outer groove. I suppose some reasons:

A: Height variance due to warp

might be small toward inner radius of record.

B: Stylus

friction on a groove might become small as per groove velocity in contradiction

with the usual theory of kinetic friction.

C: Unbalance on

revolving platter due to the stylus pressure is decreasing toward inner groove.

Rumble due to

mechanical imperfection at turntable together with Hum due to electric

induction mainly at pick-up system can be measured as SN. For

example: Playback output of certain signal groove measured as 5mV, playback

noise of plain groove measured as 10μV, then SN ratio is calculated as

54dB. I think SN ratios more than 35dB unweighted and 55dB

weighted as demanded in DIN 45500(1975) &IEC 60581-3(1978) are practical

enough as minimum performance target: it is in vain to seek extraordinary big

numbers since the SN ratio of vinyl records [due to lacquer's particle size

more or less 50 angstrom and vinylite composition with additive such as carbon black powder

etc] is usually under 65dB at 1kHz weighted by

hearing curve and under 50dB unweighted. I am astonished to read the technical

leaflet attached to Denon test record XG-7001: "This band consists of

non-modulated grooves that are provided for the purpose of measuring the

signal-to-noise ratio of the sound system...If these grooves were to have been

cut using a common cutting head, there would ensue noises such as hum, so a

special non-modulated groove cutting head without any moving

component was assembled and used to cut these grooves." I don't know how

about the plain grooves in other test records for measuring SN ratio. Anyway a

deformation-free dust-free plain groove is required for SN measurement.

IMO:

I. It is of no use to measure mechanical rumble

alone. II. The

"rumble" is an obsolete term since any modern turntable don't make

audible rumble as in the early times.

Some methods to check mechanical imperfection

or strength as the deflection of the revolving plate were presented in JIS C5521-1975 (Testing Method for Record Turntables)"

as follows:

Each measurement is tested for turntable excluding record mat

(i.e. bare platter).

Measure with dial gauge (high sensitive type with measuring pressure requirement

less than 30g).

(1) Static height variance: Without rotating a turntable, put 50g weight at the

radius 125mm on turntable and then shift the weight to the opposite place

(125mm). And check the height variance of turntable at radius 125mm. Weight 50g

is selected in consideration of the current VTF less than 10g and safe rate as x

5.

(2) Revolving height variance: With rotating turntable, check the height

variance at 10mm inside from the rim of a turntable.

(3) Revolving lateral variance: With rotating turntable, check the lateral

variance at the rim of a turntable.

Each Evaluation of (1) & (2) : The deflection of turntable =height variance

at testing point (mm) /testing point (mm) on a turntable.

Though these

JIS methods can check mechanical imperfection or strength, the method (1) is not

suitable for turntable with floating suspension. According to a test

report found in Japanese audio magazine around 1980 about first-class 11 turntables from the world (various

drives: DD/BD/Idler and various suspension and construction), static height

variance according to test (1) was maximum 0.04mm, revolving height variance

according to test (2) was maximum 0.23mm and lateral variance according to test

(3) was maximum 0.21.mm. These figures are negligible if compared with mat

flatness and record warps.

Besides above JIS, in 1978 Thorens supplied a

Rumpelmesskoppler (rumble test coupler maybe inspired by Rabinow's

USP3653255-1972) to measure mechanical rumble noise arising from spindle (literal

"rumble") - as a result generally 6dB to 10dB higher SN

comparing to conventional method using test record could be indicated by this

method (free from the quality of a test record). Hence I believe that any

modern turntable is free from a mechanical rumble and its SN is mainly

influenced by the electrical circumstances. SN is changing in accordance with

actual arrangements and nominal SN indicates only potential under ideal (not

hearing, only measuring) conditions - it is unreal for users who play

records under non-ideal conditions (various acoustic/mechanical feedback upon hearing).

Aforementioned Japanese testers (using both conventional test record and rumble

coupler) reported interestingly that the measured SN ratio

was affected by conversation in the same room (the turntables to be measured

were placed on anti-seismic board).

| Band | Kind of Recording | Effective value cm/s | Peak value cm/s | REMARKS |

| Special remark*: current test records for the time being have 10seconds recording of each signal for side A and 3 seconds recording for side B. It should not be produced anew when new test record is arranged to be made. | ||||

| Side A: Rumble Test Record as per DIN 45544 | ||||

| A1 | Left Channel | 3.83 | 5.42 | 315Hz for 15seconds* |

| A2 | Right Channel | 3.83 | 5.42 | 315Hz for 15seconds* |

| A3 | Vertical | 3.83 | 5.42 | 315Hz for 15seconds* |

| A4 | Lateral | 3.83 | 5.42 | 315Hz for 15seconds* |

| A5 | Mute band | - | - | Long plain groove with normal dense pitch to minimum radius 60mm |

| Side B: Rumble Test Record as per DIN 45544 | ||||

| B1 | Lateral | 0.38 | 0.54 | 315Hz for 15seconds* |

| B2 | Mute band | - | - | Long plain groove with pitch 0.54mm/turn (=0.3mm/s for synchronising level recorder on paper) to minimum radius 60mm in order to pinpoint the radius where an obstacle occurs. |

| Record for Rumble Test according to IEC98(1987) | ||||

| Modulation | Frequency Hz | Effective value cm/s | Peak value cm/s | Time in second |

| Left Channel | 315 | 3.90 | 5.51 | 15 |

| Right Channel | 315 | 3.90 | 5.51 | 15 |

| Vertical | 315 | 3.90 | 5.51 | 15 |

| Lateral | 315 | 3.90 | 5.51 | 15 |

| Mute band | - | - | - | |

| Remarks: 315Hz is selected because

it is located at the peak of weighted curve as well as in linear section

of unweighted evaluation curve. Under the proposition that 1kHz

reference signal velocity is 7.07cm/s eff. (10cm/s peak), the recorded

velocity 3.90cm/s eff. (5.51cm/s peak) at 315Hz

is equivalent with velocity 10cm/s at 1kHz in recording characteristic

(time constants 3180/318/75 microseconds). In the same way different frequency other than 315Hz can be selected for rumble test. For example: JIS C5521-1975 (Testing Method for Record Turntables) "signal lateral 5cm/s peak at 1kHz is selected for both SN measurement and reference tone for checking the cartridge output though it is equivalent to 45/45 velocity 3.54cm/s peak (2.5cm/s eff.)." In old JIS monophonic test record based on C 5507 before 1971, an additional groove 100Hz peak lateral velocity 1.1cm/s was included. Outputs after equalization should indicate similar values between two bands (5cm/s at 1kHz and 1.1cm/s at 100Hz). When measuring unweighted S/N of same turntable using IEC(1987), DIN(1971), JIS(1975) and NAB(1964) test records, each SN value should be ranking as IEC>DIN>NAB>JIS because of the amplitude difference of the recorded signals after equalization. Current popular specification is based on DIN 45539 (weighted)=IEC98A 1972(weighted) with sharp evaluation filter at 315Hz. Old JIS and NAB methods are virtually unweighted. In JIS method around 60dB is maximum reflecting the S/N of record itself. Noise component can be reduced with tracing on flat glass or blank lacquer plate. DIN/IEC rumble test records contained Lch/Rch/V/Lateral recordings. S/N for lateral recordings should be better than others generally but usual specifications would indicate opportune values abusing standards. Minimum S/N should be indicated as more than xx. DIN is still preferred to IEC because IEC98(1987) recommended to indicate worst value (biggest noise component) for S/N measurements. We should not be deluded with superficial specifications or big numbers appealing to innocent/ignorant consumer. |

||||

DIN 45539(measuring method)&DIN 45544 (rumble test record) both March

1971 were later accepted as international standards. Filter for unweighted curve was

modified a bit in IEC98-1987 since low frequency resonance between arm mass and

cartridge compliance might affect the unweighted measurement. Left from DIN

with my additional remark 6dB/Oct filter versus Right from DIN IEC 98 issued in

1989 as German translation of IEC98-1987. It seems that the subsonic

filter of rumble measurement as per IEC98-1987 was made as a compromise between

DIN 45539-1971 and JIS C5521(band-pass filter 300Hz-6dB/Oct &

sharp subsonic filter 30Hz 24dB/Oct or 40dB/Oct applying to the output for a

plain groove at radius 120mm for LP and at radius 80mm for EP). I

make NAB bandpass filter visualised with handwriting. I find a cool passage in

this NAB(1964): "This

measurement is intended to give a measure of electrical effect of the

low-frequency noise output of a turntable pickup combination. Since the result

depends on the equalizer, pick-up and arm characteristics as much as on the

turntable itself, it is not feasible to standardize a turntable alone. The

measurement reflects the electrical effect, not the aural annoyance value, of

the low-frequency noise. It has been found that strong low-frequency noise at a

frequency and intensity below audibility may create severe intermodulation

distortion in an audio system, and that in modern systems with extended low

frequency response, this may be more serious than the audibility of the low frequency."

I prefer the term "SN for a whole system" to "mechanical

rumble". Usually weighted S/N only is indicated since its number is

around 20dB higher than unweighted S/N. I cannot understand the meaning of

weighted S/N since motor rumble & its acoustic coupling to

plinth/arm/mat is lower than 315Hz: mostly 10Hz-250Hz. Then what is the use of low cut filter

from 315Hz? Hence spectrum analysis method has been recommended by some testers

(Yamamoto in 1971 & Ladegaard in 1977 etc). Also in IEC98A-1972, beside

conventional Method A for general use, Method B applying spectrum analysis

instrument was introduced as follows: "(This method is intended for

specialists' use, when an analytical result is required)...By means of a

measuring instrument, the voltage Uo produced by the reference signal is

measured at the output terminals of the one-third octave filter whose

mid-frequency corresponds to the frequency of the reference signal. A search is

thus made across the frequency spectrum determined, and for each of the bands

concerned, the voltage U at the output terminals of the one-third octave filters

are measured and the ratios 20 log U/Uo are determined."

There are two routes of

coupling or feedback within a turntable system: I. motor - driving mechanism -

platter - mat - record - cartridge - arm and II. record - cartridge - arm

- turntable board/plinth. I & II are in a loop. In

my test using Mechanic's Stethoscope during playing record I could hear music clearly on

arm-base while the noise at spindle was not clear. Hence I suppose friction

noise between stylus and record is more troublesome than turntable spindle noise.

Sometimes electric transformer and high-speed motor for belt or rim drive

produce higher vibration although they are suspended by rubber usually. I think

the reason for higher S/N for DD drive might be its low-speed motor centered at

spindle while other drives push platter and spindle to the side wall of bearing

sheath

so that maintenance for lubrication is required periodically. DD with

oil-sintered bronze for bearing sheath is maintenance-free for years. We find

the pro and con debate on specific driving method, but driving methods are

hardly related to sound quality though one can have fixed ideas or delusion.

One holds/appreciates what one has (ceremony of wedding?). Actual sound difference if any is arising from turntable construction (cabinet

supporting arm/turntable/motor, plinth/cushion and the stiffness of mat) and

the location of turntable system.

A or x curve to be applied on the output from a mute band: unweighted

for 20Hz-315Hz for measuring Rumpel-Fremdspannung=Rumble interference

voltage

B or y

curve to be applied on the output from a mute band: weighted with high

and low cut filters from 315Hz for measuring Rumpel-Geraeuschspannung=Rumble noise voltage

My note: In these DIN/IEC graphs, symbol +/- for dB/Oct is

omitted conventionally.

Above JIS comment "no gurantee for S/N under 30Hz" is

puzzling. It may indicate the limit of recording (cutting system for lowest

frequencies could not have enogh MFB to head). Recording of mute groove (0Hz)

had not perfect plain surface actually.

The evaluation of SN for record itself is limited

to 500Hz-10kHz etc as shown in JIS S8502.

Hum measurement as per IEC98 (1987): Use the same record as the Rumble test (315Hz velocity 5.51cm/sec using L/R/Lateral modulation) and calculate The hum voltage ratio =20log10 (cartridge output at 315Hz peak 5.51cm/sec divided by hum induction output) separately for L/R/Lateral. When measuring hum voltage, the stylus point should be located in the range of radius 5-15cm from the centre of spindle, and the needle should be setting 2.5mm above revolving platter (locating the stylus point virtually at the same level of playing actual records, no mention on record mat ???). Check the left and right channels and indicate the minimum (= worst value) for stereophonic system. IMO: The various shielding states of cartridges influence this hum ratio in actual measurements so that hum rate is not specified in recent products. In JIS C5521-1975 (Testing Method for Record Turntables) definitive method for measuring hum induction level using spherical search coil instead of cartridge is presented, but I never know it is applied actually. SN measurement as the result of whole system is already enough though SN ratio is also influenced by actual circumstances such as mat/cartridge/arm/cable/step-up transformer etc besides turntable.

DIN 45545 (1966):Gleichlauf-Meß-Schallplatten für 33 1/3 und 45 U/min (Wow and flutter test records for 33 1/3 and 45 rpm)

These records are applied for measuring wow and flutter based on DIN 45507(measuring equipment for frequency fluctuation) and DIN 45539(measuring method). Measuring frequency recorded horizontally is 3150Hz. Record itself shall be manufactured within ±0.06% (unweighted about ±0.12%) fluctuation of frequency. And wavy height change hindering optimal centering by means of using the concentric groove shall not exceed 0.3mm. The test record based on this standard was assigned to DGG.

W&F

evaluation curves: left as per DIN & right as per old JIS before 1972 for

example. NAB & JIS C5521-1975 adopted DIN/IEC

evaluation curve though there remained difference in expression among

peak/rms/mean. Anyway usual W&F analog meter will rectify the signal (with a

special slow-quasi-peak full-wave rectifier designed to register any

brief speed excursions) so that they have essentially same meaning relatively,

only showing different numbers: theoretical rate 1/0.707/0.636 for peak/rms/mean

respectively in case of sinusoidal modulating frequency. For example JIS

0.25%rms is equivalent to DIN/IEC 0.35%peak. We cannot compare the measured

specifications of equipments without knowing the measuring method and its

evaluation curve. Though this measuring method with W&F meter is established

and accepted widely, one can doubt its efficiency because it is based on

"slow-quasi-peak full-wave rectifier". Also there is the battle among measuring

methods. J.Mcknight (Ampex) reported in IEEEM (1972) (here the term

"flutter" covers wow and flutter): "The old IEEE/ANSI flutter measurement standard did not

predict subjective flutter; it also failed to specify several important

characteristics of the meter. Comerci proposed a "flutter index"

method but it was never adopted. Results of several workers were incorporated in

1962 in a German Standard (DIN) Weighted Peak Flutter measurement. The NAB

flutter measurement of 1965 incorporates the frequency weighting of the DIN

Standard, and the volume indicator of Comerci. CCIR adopted the DIN method in

1966. Experiments in the U.S.A. comparing the DIN and NAB methods showed the DIN

method to be more satisfactory, and this method is incorporated in the new IEEE

Standard 193-1971, based on an IEC draft. Circuits to achieve the desired time

and frequency responses are given, as well as suppliers of commercial flutter

meters and test records to the new standard."

Test signal must be

recorded laterally because vertical or one channel recording might indicate

other factors than wow & flutter of turntable: the movement of stylus on

sticky record may be affected more in vertical or one channel recording than

lateral recording. In my experience, the wow&flutter values measured on

test records are not reflecting the status of wow&flutter in hearing the

usual (dirty/sticky) records. Sometimes after cleaning contaminated record and

stylus, I find the wow&flutter as well as the amplitude of low frequency

resonance is reduced to some extent. Stylus drag cannot be made null in stylus

tracing method, but it can be reduced to some narrow range after cleaning

records. Hence load specification 80g for instance in direct drive turntable is

of no importance. Even if the turntable is rotating at constant speed under

fluctuating load (random frictional forces) by the stylus drag, the movement of stylus is nevertheless

affected by the stylus drag itself. This aspect of stylus/cantilever movement is

often called as "stick-slip behavior/motion".

BTW: Have you

heard Laser Turntables by Finial/ELP? They have no stylus and no stylus drag

since their pickup method is optical (the nominal diameter of laser beams each 2

micron). It is innovative and free from various mechanical problems of stylus

tracing method. However I feel the reproduced sound by Laser Turntables noisy because they are

apt to be influenced by fluffy dust. Hence they are promoting record cleaning

machine together with turntable. In usual stylus tracing method, mineral dust is

more disturbing than fluff (stylus with considerable VTF can wade or plow

fluff). There are mainly two types of dust:1) Fluff produced by our living 2)

SPM (Suspended Particulate Matter under 10micron) containing rock-mineral

(quartz etc) and clay-mineral (mica etc). Dust becomes sticky when they are

combined with oily matter evaporating at cooking or smoky particles by smoking

tobacco etc. You shall not touch recorded area by hands lest friction between

stylus and groove might be increased by fingerprints and sebum collecting dust.

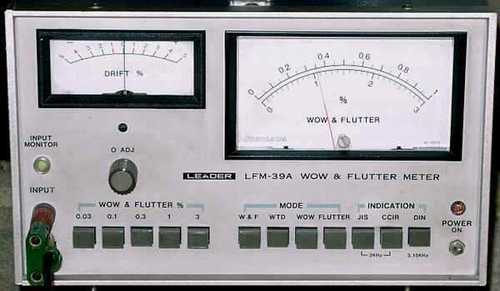

Example

of unweighted & weighted filters (Leader LFM-39A manufactured in 1979 so that

filters are same as DIN).

I tested my old equipment (cassette and

turntables) - See my Japanese Page. In my test,

cassete tape recorder/reproducer had higher rate of flutter over 6Hz compared to

turntables (maybe due to "scrape flutter" of elastic tape). Meanwhile, both

cassette reproducer and turntables had similar rate of wow under 6Hz (around

0.05%). In case of turntables, the centering of test record is affecting

measured wow rate critically. Lower flutter over 6Hz in case of turntable

is natural result from higher rotational inertia of rotor+platter+record. IMO:

Record stabiliser/weight has not increased inertia so much [W&F rate is

unchanged] while the added weight will increase the friction at turntable

spindle.

| Specifications of wow-flutter meter for example | Band-pass Filters : Unweighted | ||||

| Standard | Hz | Value | W&F range | HPF | LPF |

| NAB | 3k | Mean | 0.5-200Hz | 0.5Hz 6dB/Oct | 200Hz-15dB/Oct |

| JIS | 3k | RMS | 0.5-200Hz | 0.5Hz 6dB/Oct | 200Hz-15dB/Oct |

| CCIR | 3k (3.15kHz) | Peak | 0.3-200Hz | 0.3Hz 6dB/Oct | 200Hz-15dB/Oct |

| DIN | 3.15k | Peak | 0.3-300Hz(0.3-200Hz) | 0.3Hz 6dB/Oct | 200Hz-15dB/Oct |

| IEC | 3.15k | Peak | 0.3-200Hz | 0.3Hz 6dB/Oct | 200Hz-15dB/Oct |

Conventional measuring process of W&F: 1) reproduce the recorded signal 3kHz or

3.15kHz with cartridge or magnetic head 2) input the reproduced signal to

measuring instrument > amplifier of signal > discriminate (separate) fundamental

frequency (3kHz/3.15kHz) from modulating frequencies (W&F) > (test terminals for

oscilloscope) > add or not add evaluation curve for hearing compensation > DIN/JIS/NAB switches

for indicator (analog meter). IMO: DIN/JIS/NAB switches are

converting amplitude for indicating 1(peak):0.707(rms):0.636(mean).

CCIR(3kHz

input) position of LFM-39A has no difference from DIN(3.15kHz inut) posityion

since both adopts peak value. Hence comparable between JIS and CCIR as DIN for

3kHz source.

LFM-39A is equipped

with 4 sets of test terminals: OSC OUT 3kHz/3.15kHz, TO SCOPE AC, TO RECORDER

DC.

W&F

is similar to FM waves: original signal (music component) modulated by other

frequencies (W&F component).

My note

on conventional W&F meter. Why fundamental 3kHz or 3.15kHz is selected? It

is said that the sensibility peak of human ears is located around 2kHz-3kHz.

Moreover if fundamental frequency is nearer to modulating frequency, then more

sharp LPF is required otherwise W&F 0.1% (-60B) cannot be measured. The

reason why modulating frequency upto 200Hz is enough might be another story

(acoustic psychology). The acoustic psychology (tests carried out by Eberhard Zwicker

in 1952 and NHK in 1955 etc) tells us that human ears are most sensitive to wow

(modulating frequency) 3-6Hz so that weighted curve for hearing compensation is

decided. Upon my hearing of FM waves generated experimentally, even through PC

speakers I can hear clearly WOW of 3-6Hz upto -50dB=0.3% as something like

beating echo sound while I could not discern W&F of any frequency at less

than 0.1% - thus I can reconfirm conventional theory: "there is no real

problem in sound quality as far as continuous W&F (excluding any peaked

thrust from groove irregularity) is lower than 0.1%". I suppose this is

the reason why IEC recommends groove eccentricity to be within 0.2mm. Wow caused

by 0.2mm eccentric groove: 0.14-0.33% for music band for LP can be reduced to less than 0.1%

weighted with hearing compensation=1/3(-10dB at 0.55Hz according to chart). The minor

frequency difference between 3kHz and 3.15kHz is negligible because the filter

band of W&F meter can handle centre frequency +/- 10% as input. Usually the

measured figures weighted with hearing compensation (evaluation curve) is

indicated as representative value.

When the frequency counter is mounted on

W&F measuring instrument, its counter shows centre frequency so that it works as drift meter

(indicating average frequency in certain time scale)- I could not see any swing

of drift meter during my measurement of W&F by above instrument. Frequency

counter with smallest "gate time" is required to see actual rapid frequency

variation, hence it is impossible to measure wow-flutter

by usual rpm meter or frequency counter (indicator of the normalised results

after sampling within gate time). Some

W&F meters can indicate W&F unweighted/W&F weighted/Wow/Flutter

separately in combination of indication JIS/DIN/NAB etc. 0Hz-6Hz as wow and

6-200Hz as flutter in many conventional W&F meters (when modulated with

threshold frequency 6Hz and 1% amplitude, meter shows 0.7% each for wow and

flutter). Meanwhile current IEC calls 0.1Hz-10Hz as wow range and over 10Hz as

flutter range. Now IEC standard based on DIN remains valid. Nobody care about

the end of standards: Almost all JIS standards about analog records and

equipment were stamped as "abolished" by 1984 or 1994 at the latest while some

old standards are walking alone as living ghosts without knowing their death.

IEC would adopt 20 years rule from last revision then IEC98(1987) too becomes

such living ghost.

Conventional W&F measuring method in order to get simple numbers is almost dated because W&F and rumble and low frequency resonance are involved in sound quality. JVC applied for Japanese patent 1981-47903 (patented as 1279820) proposing test record 3Hz-125Hz (vertical amplitude 20 micrometers) sweep superimposed with 3kHz or 3.15kHz. Its measuring method: reproduced sound>flat amplifier>W&F meter>(discriminated frequencies)>recorder. What is notable in this documents: "In some cases the low resonance between cartridge and arm does not affect the higher frequencies of music while in other cases the heavier intermodulation and degradation in sound quality arise from rather flat response of lower frequencies". This method intends to know the sound quality of record player as system including arm and cartridge. I think Ladegaard already proposed similar measurements in his Audible Effects of Mechanical Resonances in Turntables (AES Convention 1977) which is downloable from Vinyl Engine as article. You cannot get simple numbers by these methods, but are able to know the sound quality reproduced by record player as system. In my experiment too the W&F waves look different among cartridges even if the W&F rate is similar (I suspect FIM of cartridge in operation is much different from nominal value - frequency dependant). Each reproduced sound results from unique compound of several factors.

DIN 45549 (1980):Abtastfähigkeits-Meßschallplatte (Tracking ability-test-record)

Object:

In the first place this test record shall be applied for trackability test at

315Hz and 10kHz. It covers supplementary tests for trackability in mid

frequencies for FIM measurements, sensitivity and rectangular modulation.

Vertical modulation angle is 23degree for stereo recorded bands except B9-B16

monaural bands which are recorded laterally/sidewise=Seitenschrift. Bands

A1-A2: 1kHz effective velocity 5.6cm/sec(=peak 8cm/sec) as reference tone, Bands

A3-A7: pulse 10kHz with a 250Hz repetition, peak velocity 8-20cm/s interchanging

between L/R for pulse test. Bands A8-12: 300Hz/3000Hz (4:1), 300Hz component

peak velocity 4-10cm/s interchanging between L/R for frequency intermodulation

test (each 2.5dB up for 400/4000Hz when playing at 45RPM instead of 33.3RPM)-

see DIN 45542. Bands B1-B2: 1kHz effective velocity 5.6cm/sec(=peak 8cm/sec) as

reference tone. B3: Rectangular wave 1kHz cut as triangle with amplitude 11μm.

B4-B8: complex (Doppel) tone of 1.8kHz+2.2kHz (1:1) momentary peak velocity

10-25cm/s interchanging between L/R. Bands B9-16: 315Hz peak signal amplitude 50μm-120μm.

Distortion rate in high frequency is measured with pulse 10kHz/250Hz while

trackability in low frequency is measured with high amplitude horizontal

recording of 315Hz. The distortion for high frequency after passing special

filter shall be Dh=U(250)/U(10000) x 100 in %. I saw similar equation in

leaflet attached to Shure Test-record TTR-103

(45rpm)

(10.8kHz pulsed high frequency test with a 270Hz repetition). In low-frequency

test Shure TTR-103 indicated Amplitude Intermodulation Distortion with

400+4kHz at 45rpm based on SMPTE (Society of Motion Picture & Television

Engineers) method. Quite different measuring methods for IMD measurement are

imaginable: record Pink Noise excluding certain bandwidth and compare it with

reproduced output range to measure distortion fallen in the band. Simple

method for measuring tracking ability was once indicated by IEC98A in 1972 which

defined the tracking ability as the minimum tracking force required to maintain

contact between reproducing stylus and both groove walls on a given test record

having "the average recorded levels found on disk records"(45

degrees R or L one channel sweep 80-8000-80Hz: max 18cm/s peak around

2kHz) I imagine two objections: 1) The cartridges with highest compliance

and lowest VTF are not always having highest tracking ability. In my diabolic

definition: High-compliance cartridge is a type of cartridge which cannot endure

drastic change of VTF. 2) What are the

average recorded levels? Practically for tracking ability test, some audiophiles use

the specific bands of commercial records which contain the difficult part

(mostly high frequency & high amplitude passage with sibilant sounds) for

cartridges. Hence the tracking ability tests are developed to more complicated

methods maybe based on Shure: "A Practical High-Frequency Trackability Test

for Phono Pickups" JAES in April 1972 etc. IMO: Tracking ability test in

98A in 1972 was based on average (its moderate intention is known

from test record size 7inch and speed 33.3rpm) while the advanced methods are

based on the extremity (as some audiophiles demand). Once I found difficulty in obtaining average

performance reproducible everywhere & anytime as some old British Standards

(rpm of car engine) require, whereas other standards allow to indicate maximum performance

under optimum or optional condition. I don't know which is

more user-friendly, but audiophiles are usually fond of extreme rate.

Current IEC 60098 Clause 14.9 Trackability is suggesting to use three

kinds of test signals:

-A. Trackability at low-frequency with 315Hz/Horizontal

Modulation. Its performance is indicated by max. amplitude in mm up to which

a cartridge at recommended tracking force can trace without apparent distortion and

tracking problem. The smaller rate of amplitude shall be adopted when the

performance differs between channels.

-B. Trackability at low-mid frequency with sweep from 1kHz to

20Hz/Horizontal Modulation. The output of these frequencies are equalised with

IEC/RIAA reproduction characteristics so that the output voltage is stable

within these frequencies. Hence velocity shall be indicated along with

respective frequency measured. Its performance is indicated by max. velocity in cm/s up to

which a cartridge at recommended tracking force can trace without apparent distortion

and tracking problem. The smaller rate of velocity shall be adopted when the

performance differs between channels.

-C. Trackability at high-frequency with pulse 10kHz (with repetition at

250Hz) LRLRLRLRLR. The output is amplified linearly and then filtered into

components. Its performance is indicated by max. velocity in cm/s up to

which a cartridge at recommended tracking force can trace without excessive distortion

and tracking problem. The smaller rate of velocity shall be adopted when the

performance under the specified distortion rate differs between channels. Also

distortion rate in high frequency shall be indicated.

Why impulse instead of continuous 10kHz recording? I suspect that continuous

10kHz recording at very high velocity can burn out driving coils of cutterhead

as specified by Neumann SX-74 with cutter drive logic SAL74 as under. Lateral

28.5cm/s peak can be converted to stereo (45 direction) around 20cm/s peak. Even

if juvenile cutting engineers fumble with Neumann and try to record continuous

10kHz 20cm/s, the cutting system can remain undamaged as far as cooling

equipment is added.

| Band | Kind of Recording | Effective value cm/s | Peak value cm/s | REMARKS |

| How to use this test record: linear flat amplifier (without RIAA/IEC reproducing characteristics) should be used. | ||||

| Side A: Tracking Ability Test Record as per DIN 45549: A test record based on this standard was produced by DGG. | ||||

| A1 | Left Channel | 5.6 | 8 | Reference Tone Level = 0dB 1kHz 15seconds |

| A2 | Right Channel | 5.6 | 8 | Reference Tone Level = 0dB 1kHz 15seconds |

| A3 | L/R | 5.6 | 8 | Impulse Test 10kHz

with repetition at 250Hz: (every packet of impulse:

8wavesx10kHz+mute=10kHz0.0008s+mute0.0032s)

L/R interchanging every 20 seconds |

| A4 | L/R | 7.1 | 10 | |

| A5 | L/R | 8.8 | 12.5 | |

| A6 | L/R | 11 | 16 | |

| A7 | L/R | 14 | 20 | |

| A8 | L/R | 2.8 | 4 | FIM (frequency

intermodulation) Test 300/3000Hz (4:1), the velocities of 300Hz

component are as indicated in left column.

L/R interchanging every 12 seconds for 33 1/3 rpm By rotating at 45rpm, test signal approx. 400/4000Hz and L/R interchanging every 9 seconds [EP/LP=rpm ratio 1.35, 1.35x300Hz=405Hz] |

| A9 | L/R | 3.5 | 5 | |

| A10 | L/R | 4.5 | 6.3 | |

| A11 | L/R | 5.6 | 8 | |

| A12 | L/R | 7.1 | 10 | |

| Side B: Tracking Ability Test Record as per DIN 45549: A test record based on this standard was produced by DGG. | ||||

| B1 | Left Channel | 5.6 | 8 | Reference Tone Level = 0dB 1kHz 15seconds |

| B2 | Right Channel | 5.6 | 8 | Reference Tone Level = 0dB 1kHz 15seconds |

| B3 | L/R |

Rectangular wave 1kHz cut as triangle shape in groove with amplitude 11μm. L&R each 15seconds |

||

| B4 | L/R | 7.1 | 10 | Difference Tone

Test by 1.8kHz+2.2kHz (1:1)

L/R interchanging every 12 seconds |

| B5 | L/R | 8.8 | 12.5 | |

| B6 | L/R | 11 | 16 | |

| B7 | L/R | 14 | 20 | |

| B8 | L/R | 18 | 25 | |

| B9 | Lateral | 7.0 | 9.9 | 315Hz peak amplitude 50microns (displacement 0 to peak) |

| B10 | 8.4 | 11.9 | 315Hz peak amplitude 60microns (displacement 0 to peak) | |

| B11 | 9.8 | 13.9 | 315Hz peak amplitude 70microns (displacement 0 to peak) | |

| B12 | 11.2 | 15.8 | 315Hz peak amplitude 80microns (displacement 0 to peak) | |

| B13 | 12.6 | 17.8 | 315Hz peak amplitude 90microns (displacement 0 to peak) | |

| B14 | 14.0 | 19.8 | 315Hz peak amplitude 100microns (displacement 0 to peak) | |

| B15 | 15.4 | 21.8 | 315Hz peak amplitude 110microns (displacement 0 to peak) | |

| B16 | 16.8 | 23.8 | 315Hz peak amplitude 120microns (displacement 0 to peak) | |

DIN 45550 (1976):Schallplatten-Hüllen; Außen- und Innenhüllen, Maße und Beschriftung (Record sleeves; outer-and inner-sleeves, dimensions and inscription) & DIN 45551 (1976): Schallplatten-Kassetten für 30 cm-Schallplatten; Maße und Beschriftung (presentation-box for 30cm-record; dimensions and inscription)

The German people really likes norms - I never imagined such specifications were existing. Jacket size for LP is width315xheight311 with side opening (inner thickness 2mm). Basic inner sleeve for LP is almost square(w309xh304) with circular cut for label. DIN 45536(Mono 17cm)/45546(Stereo 17cm) &45537(Mono 25/30cm)/45547(Stereo 25/30cm) are quoted as specifications of records though sleeve for 25cm records is not specified (maybe by 1976 the production of MP=medium play records is much reduced). See also my Japanese page about jacket, inner sleeve & box.

My Summary Note:

These industry standards (IEC/DIN/NAB/JIS) cover almost all the products specifying minimum requirements for not only soft but mainly reproducing equipment available at the times. Hence their specifications don't tell anything new/essential on music recorded groove radii. One thing I feel curious in IEC60098(1987) is about inner groove radius 63.5mm which is related to the performance of automatic player (my Kenwood P-5E Linear Tracking Player will lift arm around 60mm radius before finishing groove located around 54mm radius). In 1987 when CD players became already popular, it might be thought that record players could be also automated as seen mostly in low and middle price range of record players.

It seems funny to me that some long time play-back records have not utilized inner radii to maximum. For example, one EMI/Seraphim record: Schubert String Quartet No. 14(Death and Maiden)=38min26sec on one side (pseudo-stereo made from monaural recording) and Piano Quintet (Trout)=32 minutes on other side (both inmost recorded radii are larger than 70mm). Usually it is said that LPs have 150-300 grooves per inch. Hence when music band width is max 83mm(146.5-63.5) then 490-980 grooves for 15-29minutes. The above EMI/Seraphim case: 38min26sec/75mm=about 433 grooves/inch - too fine pitch! I suppose that this record has not utilized extreme inner groove radius in order to avoid (expected) inner tracing distortion by the sacrifice of out-put level (dynamic range and S/N).

Lateral

Tracking Error and its distortion: it might be critical (audible) only with

recent elliptical/line contact tip in stereo groove esp. if anti-skating

mechanism is not equipped on overhang-offset arm. With spherical tip in monaural

groove, its distortion is not so critical even without anti-skating mechanism

(or other distortions due to spherical tip are enough to mask this relatively

small distortion?). Considering the inner groove is rarely less than 70mm for LP

and if the inmost music groove radius is 63.5mm and outmost music groove radius

is 146.3mm, an optimum arm design based on Baerwald method can be as follows:

Linear Offset for Baerwald method i.e. peak distortion rating similar at

63.5/88.561/146.3mm is 96.04mm (instead of current Baerwald type linear offset

around 93.5mm)

Null points: 69.2/122.8mm (instead of current Baerwald type null points:

66/120.9mm)

In comparison with current Baerwald type, this new design has wider offset angle

and also increased overhang (hence higher anti-skating force required to mate

with increased side thrust force).

Anti-skating mechanism is problematic. It is rare that the anti-skating force

will match side thrust force due to eventual friction forces. Some Thorens arms

have 4 different scales for anti-skating: wet/dry x spherical/elliptical

tip. The following graph shows imbalance of pressures on flank L/R for

three representative designs of geometry (Stevenson/Baerwald/Loefgren) when

anti-skating device is omitted (parameters: effective coefficient of

stylus drag 0.3 and effective length of arm 231.2mm).

Note: theoretically the true coefficient of friction = 1/(SQRT(2) ) of the

measured or empirical value since vertical stylus pressure is to be divided statically

into VTF/(SQRT(2) ) each on groove flank. Then stylus drag force is

[VTF/SQRT(2)]*2*coefficient of friction=VTF*SQRT(2)*coefficient of friction. This tricky calculation is based on armchair theories

because the VTF cannot be actually divided evenly during stylus drag.

Hence usually effective coefficient of stylus drag as empirical results

is assumed to be theoretically equivalent to SQRT(2)*coefficient of

friction. This coefficient of stylus drag 0.3 (coefficient of friction 0.212)

for example is rather too small in comparison to the past investigations

(coefficient of stylus drag 0.27-0.5 by Rangabe or 0.25-0.55

by JVC-1979 as shown in the following table). The dynamic

load of stylus pressure on the groove is never constant. Many factors are involved in the nature of stylus

friction: stylus contact profile

and record elasticity (depth of stylus dipping into groove wall by VTF - see my stylus.xls), groove

modulation amplitude and frequency, mechanical impedance of stylus movement

corresponding to such groove characteristics, and mostly dust and sticky

substance

on contaminated records and stylus tip.

There are

some drawbacks in the

actual performances of anti-skating devices:

1) The lateral balance is affected

by adding bias force.

2) "Swinger" action of arm by the eccentric groove

or off-centre record increases the stylus side-pressure more by adding this device.

3)

Non-mechanical contact such as magnetic or electromagnetic anti-skating device

may be ideal.

Users after 1970s are satisfied simply by

finding that such fashionable device or accessory is equipped on arm. IMO:

Basically it is better not to use this device. Increase VTF around 10% if

necessary. In my experience it is better than adjusting bias force of

anti-skating device. To use such device or not to use is up to

you.

|

The following rates seem to be indicating stylus

drag coefficient instead of coefficient

of kinetic friction: |

|||

|

Groove modulation |

Spherical tip (17μ) | Elliptical tip (7x17μ) | Shibata tip (7x65μ) |

| Mute plain groove | 0.25 | 0.3 | 0.28 |

| 3~10cm/s | 0.3 | 0.4 | 0.35 |

| 8~16cm/s | 0.45 | 0.55 | 0.5 |

| 30kHz 5cm/s | 0.4 | 0.5 | 0.45 |

Note that

the deflection of cantilever due to the side thrust force (skating force) is too

small that one cannot adjust anti-skating force seeing the deflection of

cantilever (see the following drawing and think coolly on the normal human

eyesight). When we recognise apparently cantilever deflection during playing a

record, then it has a defective cantilever or anti-skating force is too high.

Hence both Dual Skate-0-meter and Orsonic

Lateral Pressure Detector were invented as magnifying

device to see cantilever deflection. Lehmann and Harnisch invented Dual "Skate-0-meter" and

commented in their US Patent 3328037-1967: "To

permit accurate adjustment, hitherto a record was used which had no grooves but

only a smooth surface. The pick-up with its scanning needle was placed on the

rotating disc and the antiskating so adjusted that the pickup remained

stationary. Investigations have proved that this method is only apparently

accurate. The actual friction of the scanning needle in a sound groove is

different. Direct measurement of this friction, which as such gives a direct

measure for the necessary anti-skating force, is however relatively complex."

And they recommended to apply Skate-0-meter on a plain groove with normal

recording pitch while Nakatuka in his USP4183537-1980 recommended to apply

Orsonic Lateral Pressure Detector on sound grooves for anti-skating adjustment.

Also note that usually the bottom profile of stylus is unspecified or unpolished

since such part of stylus is designed simply to have enough clearance from the

bottom of groove. The higher stylus drag for higher frequency and higher

amplitude can be attributed to the mechanical impedance of respective pick-up.

In order to move stylus in higher frequency, there arises instantaneous higher

stylus pressure to groove walls as reaction from undulating walls. Thus

effective low mass or low inertia of moving parts is required for tracing such

high frequency recorded groove with relatively light stylus down-force.

Mechanically a pickup has three different (stiffness or

compliance/resistance/mass or inertia) controlled domains in mechanical

impedance curve. Typically: stiffness controlled domain (20Hz-1kHz* see note),

resistance-domain (1kHz-10kHz or around) and mass- or inertia-domain (around

10kHz and upward) though its domain and curve of mechanical impedance (dyne

sec/cm) is shifting up or down as per the make and design.

*Note: "Compliance at 100Hz"

in the specification for some Japanese cartridges must be considered in this

lower frequency range. It is often misunderstood as if it would be intended for some

calculations at arm-cartridge resonance around 5Hz-20Hz. In fact it indicates

an index convertible to a mechanical impedance at lower frequencies for the

purpose of obtaining the vertical stylus pressure required for safe tracking. It

is concerned with tracking ability and not with resonance. Hence it is of no use for

amateurs who try resonance calculation. Frankly speaking the required VTF value

instead of compliance value is enough for users. Since 1970s Shure has not

indicated "misleading" compliance value, but instead indicating VTF value sometimes

together with trackability chart (max. traceable velocity [cm/s] per

frequency under specific VTF). The mechanical impedance [dyne sec/cm]

chart for full frequency range (technically equivalent to Shure trackability

chart) is more important than compliance at lower frequencies. Please see the

relation among mechanical impedance, compliance and recorded velocity as

explained in technical sheet

attached to DENON

test record XG-7001. By measuring the mechanical impedance, it is possible

to know the stylus pressure required for tracing on specific velocity of

record. Think on the relation

between Shure trackability chart and Denon mechanical impedance chart i.e.,

between velocity and VTF. Naturally it is concerned with the recordable and

recorded velocity on actual records.

According to the AES report in 1968 by Toshiba engineers: "Trackability

Test by Complex Tones and Biasing Force Effects of Phonograph Pickups": "Some

of the so-called "high compliance" cartridges have produced larger

I.M.D. under the specified tracking force than those of relatively low

compliance. For low modulation level both cartridges have similar

characteristics, but for high modulation level the former are much effected by

side thrusts. Side thrust less than 0.05g is allowed for I.M.D. less than 10%

for high compliance cartridges.

From this, "high compliance" cartridges operating under small tracking

force are not necessary good from the viewpoint of degradation by biasing forces".

My note: I cannot believe 0.05g can be threshold for IMD less than 10% since

all cartridges mounted on swing arms have received temporary side thrust more

than 0.05g. Usual side thrust and antiskating bias at stylus point are

considered average 10% of VTF. We must consider the nature of side forces

(temporary or steady) and wherefrom (groove modulation amplitude and velocity or

arm geometry etc). Naturally force from groove modulation (displacement) is generally

larger than side thrust from arm geometry. BTW: In 1969 other engineers of

Toshiba invented Photo-electric pick-up(GB1281912

& DE1941407)which could measure VTF as well as effect from side

thrust. It is embodied as pickup C-100P and preamplifier SZ-1 enabling proper

VTF adjustment although the biasing mechanism is omitted from embodiment.

In

JVC book(1979), Shibata as one of the writers commented as follows: "Cantilever

deflection can reach more than a few degrees

by side thrusts so that

tracking angle error distortion is increased. To avoid such occurrence, the

compliance should be kept not excessively high, and linear tracking arm (not

swinging but linear shifting) is preferable". IMO: Deflection of

"a few degrees" is contradicting to above drawing, but under certain

stress loading for long time, cantilever may be deflected and not reverted to

the normal position (permanently deformed damper). In my experience, high

compliance cartridge with soft damper tends to bent its cantilever angle after

long use: outward bent under 0 anti-skating force, inward bent under excessive

anti-skating force. It is not easy to know the

actual operating angles in both antiskating bias and tracking angle adjustments

though some audiophiles are fond of such adjustments based on some devices. I

find some cartridges having the cantilevers not located in the centre from the

first. Personally I don't believe the efficiency of antiskating devices